Clean Hydrogen Power High-Purity Environmentally Friendly High Pressure Hydrogen Nitrogen Oxygen Gas Piston Compressor

Cooling method:air/water/mixed

Driving method:motor/diesel engine

Control method:PLC automatic control

The entire nitrogen unit is integrated in the container body, which can be easily moved and transported. Nitrogen with a certain pressure and purity from the nitrogen generator is compressed to 35MPa by a reciprocating piston compressor. Thewhole unit includes a screw compressor,a purification system, an air buffer system, an adsorption nitrogen production system, a nitrogen buffer system, a nitrogen booster system, a control system, a base and a sound insulation and heat preservation metal cover.

|

No.

|

Model

|

Volume flow

|

Exhaust pressure

|

Power

|

Pry Type

|

Dimension

|

Weight

|

|

Nm³/hr

|

MPa

|

kW

|

mm

|

||||

|

1. Integrated adsorption nitrogen injection system (one skid completes all functions of air compressor, nitrogen production, and boosting to 50MPa)

Main configuration: screw compressor, dryer, three-stage buffer tank, five-stage filtration, nitrogen generator, booster (frequency conversion), container |

|||||||

|

1

|

BOBFN-450/350

|

450

|

35

|

220

|

1 pry

|

9000×2300×2700

|

13000

|

|

2

|

BOBFN-600/350

|

600

|

35

|

315

|

1 pry

|

9000×2300×2700

|

17500

|

|

3

|

BOBFN-900/350

|

900

|

35

|

440

|

2 pry

|

9000×2300×2700

|

26000

|

|

4

|

BOBFN-1200/350

|

1200

|

35

|

630

|

2 pry

|

9000×2300×2700

|

35000

|

|

2. Split adsorption nitrogen production system (two or three skids complete all functions of air compressor, nitrogen production, and pressurization to 35MPa high-pressure nitrogen)

Main configuration:screw compressor, dryer, three-stage buffer tank, five-stage filtration, nitrogen generator, booster (frequency conversion), container |

|||||||

|

1

|

BOBFN-450/350

|

450

|

35

|

220

|

2 pry

|

7500×2300×2700

|

15000

|

|

2

|

BOBFN-600/350

|

600

|

35

|

315

|

2 pry

|

8500×2300×2700

|

18000

|

|

3

|

BOBFN-900/350

|

900

|

35

|

440

|

3 pry

|

8500×2300×2700

|

29000

|

|

4

|

BOBFN-1200/350

|

1200

|

35

|

630

|

3 pry

|

8500×2300×2700

|

40000

|

|

3. New air (nitrogen) dual-purpose nitrogen production system (nitrogen generator + air (nitrogen) dual-purpose compressor)

Main configuration:screw compressor, dryer, three-stage buffer tank, five-stage filtration, nitrogen generator, booster (frequency conversion), container |

|||||||

|

1

|

BOBFN-450/250

|

450

|

25

|

132

|

1 pry

|

7500×2300×2700

|

8000

|

|

2

|

BOSF-7/250

|

7

|

25

|

160

|

1 pry

|

7000×2300×2500

|

8000

|

|

3

|

BOBFN-600/250

|

600

|

25

|

180

|

1 pry

|

7500×2300×2700

|

8000

|

|

4

|

BOSF-10/250

|

10

|

25

|

200

|

1 pry

|

7000×2300×2500

|

8000

|

|

Model

|

Flow

(Nm3/h) |

Inlet Pressure

(MPa) |

Exhaust Pressure

(MPa) |

Form & Stages

|

Lubrication Method

|

Cooling method

|

Power

(KW) |

Dimension

(mm) |

Weight

(kg) |

|

BOZWF-1.0/1-18

|

100

|

0.1

|

1.8

|

Z type

2 stages |

oil-free

|

air cooled

|

15

|

2000*1600*2200

|

1800

|

|

BOVWF-2.5/0.5-18

|

200

|

0.05

|

1.8

|

V type

2 stages |

oil-free

|

air cooled

|

30

|

3500*2200*1800

|

3500

|

|

BOVW-1.8/(1-2)-70

|

235

|

0.1-0.2

|

7

|

V type

4 stages |

oil-free

|

air cooled

|

55

|

4500*2500*2000

|

4500

|

|

BOZWF-1.5/(1-2)-16

|

260

|

0.1-0.2

|

1.6

|

Z type

2 stages |

oil-free

|

air cooled

|

22

|

2000*1600*2200

|

2000

|

|

BODW-6/0.2-3

|

300

|

0.02

|

0.3

|

D type

2 stages |

oil-free

|

air cooled

|

45

|

3500*2000*1500

|

3500

|

|

BOZW-3.6/(0.5-1)-3

|

325

|

0.05-0.1

|

0.3

|

Z type

1 stage |

oil-free

|

air cooled

|

22

|

2000*1500*1700

|

2000

|

|

BOVW-7.5/0.05-2.5

|

400

|

0.005

|

0.25

|

V type

1 stage |

oil-free

|

air cooled

|

45

|

3500*2000*2500

|

4000

|

|

BODW-3.85/(1-1.5)-220

|

450

|

0.01-0.15

|

22

|

D type

4 stages |

slightly oil

|

air cooled

|

132

|

5500*3000*2200

|

6500

|

|

BODF-5/(0.2-1)-250)

|

600

|

0.02-0.1

|

25

|

D type

4 stages |

slightly oil

|

air cooled

|

160

|

6000*2500*2500

|

6000

|

|

BOVW-2.3/(3-6)-40

|

655

|

0.3-0.6

|

4

|

V type

3 stages |

oil-free

|

air cooled

|

110

|

3500*2500*2000

|

6500

|

|

BODW-3.5/(2-5)-30

|

815

|

0.2-0.5

|

3

|

D type

2 stages |

oil-free

|

air cooled

|

132

|

4000*2800*2000

|

6000

|

|

BODF-5/(1-2)-250

|

900

|

0.1-0.2

|

25

|

D type

4 stages |

slightly oil

|

air cooled

|

185

|

6500*2500*2500

|

6500

|

|

BOVWF-18/0.4-2

|

1000

|

0.04

|

0.2

|

V type

1 stage |

oil-free

|

air cooled

|

90

|

4000*2000*2530

|

5500

|

|

BOVWF-15/0.5-3

|

1200

|

0.05

|

0.3

|

V type

2 stages |

oil-free

|

air cooled

|

75

|

4500*2200*1800

|

5000

|

|

BODW-3.65/(5-8)-45

|

1400

|

0.5-0.8

|

5

|

D type

2 stages |

oil-free

|

air cooled

|

185

|

4500*2800*2000

|

7400

|

|

BODW-6.7/(2-5)-26

|

1500

|

0.2-0.5

|

2.6

|

D type

2 stages |

oil-free

|

air cooled

|

185

|

5000*2800*2000

|

8500

|

|

BODW-0.65/(40-50)-250

|

1550

|

4.0-5.0

|

25

|

D type

2 stages |

slightly oil

|

air cooled

|

160

|

6500*3000*2600

|

8500

|

|

BODW-14.5/(1-3)-5

|

2250

|

0.1-0.3

|

0.5

|

D type

1 stage |

oil-free

|

air cooled

|

110

|

4000*2500*2000

|

4500

|

|

Model

|

Flow

(Nm3/h) |

Inlet Pressure

(MPa) |

Exhaust Pressure

(MPa) |

Form & Stages

|

Lubrication Method

|

Cooling method

|

Power

(KW) |

Dimension

(mm) |

Weight

(kg) |

|

BOZF-0.4/ 2-250

|

60

|

0.2

|

25

|

Z type

4 stages |

slightly oil

|

air cooled

|

18.5

|

2800*2200*1600

|

2500

|

|

BOZWF-0.81/ (1~3)-25

|

120

|

0.1~0.3

|

2.5

|

Z type

3 stages |

oil-free

|

air cooled

|

22

|

1000*1580*1870

|

2000

|

|

BODW-0.85/(3~4)-250

|

180

|

0.3~0.4

|

25

|

D type

4 stages |

slightly oil

|

air cooled

|

55

|

2400*1800*1500

|

8500

|

|

BOZWF-0.46 /(5~10)-250

|

200

|

0.5~1.0

|

25

|

Z type

4 stages |

slightly oil

|

air cooled

|

45

|

3000*2200*1600

|

2500

|

|

BODW-1.34/2-250

|

208

|

0.2

|

25

|

D type

4 stages |

oil-free

|

air cooled

|

55

|

3400*2200*1600

|

6500

|

|

BOZW-2.9/14.2-20

|

220

|

1.42

|

2

|

Z type

1 stage |

oil-free

|

air cooled

|

55

|

2200*1600*1200

|

1200

|

|

BODWF-0.21/(20~30)-250

|

270

|

2~3

|

25

|

D type

2 stages |

slightly oil

|

air cooled

|

45

|

3200*2200*1600

|

6500

|

|

BODWF-6.0/5

|

300

|

normal pressure

|

0.5

|

D type

2 stages |

oil-free

|

air cooled

|

37

|

2000*1600*1200

|

3500

|

|

BODW-6.8/0.05-40

|

200~400

|

0.005

|

4

|

D type

4 stages |

oil-free

|

air cooled

|

90

|

2400*1800*1500

|

6500

|

|

BOVW-2.0/(2~4)-25

|

410

|

0.2~0.4

|

2.5

|

V type

3 stages |

oil-free

|

water cooled

|

55

|

3400*2200*1600

|

5000

|

|

BODW-1.2 /6-250

|

420

|

0.6

|

25

|

D type

4 stages |

slightly oil

|

air cooled

|

90

|

3400*2200*1600

|

7500

|

|

BODW-2.7/2-200

|

420

|

0.2

|

20

|

D type

4 stages |

slightly oil

|

air cooled

|

110

|

3400*2200*1600

|

6200

|

|

BODWF-5.8/0.5-5

|

400~500

|

0.05

|

0.5

|

D type

2 stages |

oil-free

|

air cooled

|

37

|

2000*1600*1200

|

3500

|

|

BOZWF-0.16/60-250

|

480

|

6

|

25

|

Z type

2 stages |

slightly oil

|

air cooled

|

45

|

3000*2200*1600

|

2500

|

|

BOVW-3.22/2-250

|

500

|

0.2

|

25

|

V type

4 stages |

slightly oil

|

air cooled

|

132

|

3400*2200*1600

|

6500

|

|

BODW-3.0/3-250

|

500

|

0.3

|

25

|

D type

4 stages |

slightly oil

|

air cooled

|

160

|

4800*2200*1600

|

9500

|

|

BODW-10/2

|

510

|

normal pressure

|

0.2

|

D type

1 stage |

oil-free

|

water cooled

|

37

|

2000*1600*1200

|

3500

|

|

BOVW-8.0/0.3-25

|

540

|

0.03

|

2.5

|

V type

3 stages |

oil-free

|

air cooled

|

90

|

2400*1800*1500

|

7500

|

|

BODW-1.1/10-250

|

600

|

1

|

25

|

D type

3 stages |

slightly oil

|

air cooled

|

160

|

4800*2200*1600

|

9000

|

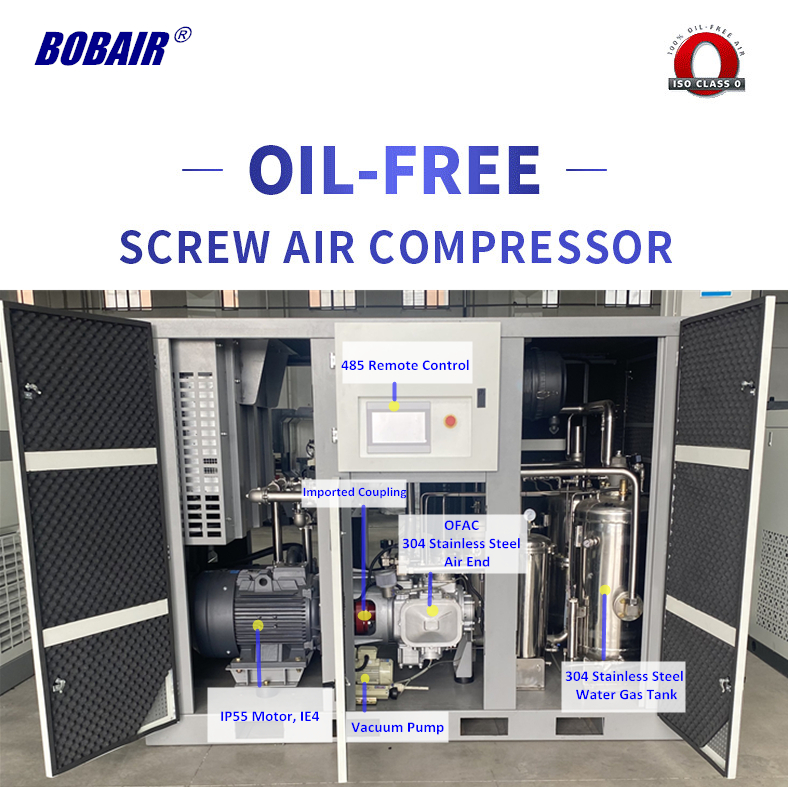

The brand “BOBAIR, specializes in the R&D, manufacturing, sales and service of compressors, oil-free compressors and air end, special gas compressors, various air compressors and post-processing equipment, providing customers with High-quality, environmentally friendly and efficient air system solutions and fast and stable technical services.

Why Choose BOBAIR Oil-free Screw Air Compressor

1. Mitsui technology, can replace Mitsui air end 1:1.

2. Highest ultra precision air end manufacturer in China, failure rate nearly 0.

3. Comes with 3-stage purifier, tap water(daily used water) is workable.

4. Easiest maintenance, 0 Emission.

5. simple structure, easy to use.

6. with 485 remote switch.

Jiangxi Bobai has launched a completely new range of high efficiency, oil-free two-stage rotary screw compressors to further enhance its successful. These high output oil-free machines now cover a wide flow range from 6.0 to 40.0m3/min, the pressure range from 20bar to 40bar.

High-pressure compressed air is used for blowing bottles.

The pressure depends on the container’s design, wall thickness, blow speed, and so on. The bottles with thick walls, sharp edges, and special shapes need higher pressure. Generally, the stretch blow molding requires about 10~25bar for pre-blowing and about 40bar for the bottle-blowing process. The trend for PET bottle-blowing machines is to reduce the blow pressure as much as possible for energy saving.

The bottles should be cleaned with compressed air before filling the water, beverage, cooking oil and so on.

If the air is contaminated, it will influence the flavor and odor, causing health problems.

For screw type, the air is compressed to 7~8bar at the first screw compression stage, there is no need to cool and the air goes into the second stage screw air end, finally achieving 30~40bar air discharge directly without cooling. Rotation speed 3000r/min, zero loads. About 50℃, no heat waste, Ideal isothermal compression.